Trusted welding solutions provider Since 1990

Providing solutions in

metal joining for some of the leading brands in India.

Our vision is to work towards total customer satisfaction through innovation and continues improvement in our process and team work.

To the product area

To be a world class supply partner specializing in complete welding solution & sheet metal sub assemblies.

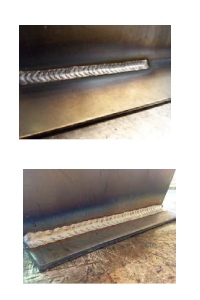

To the product areaSreeram Industries, an ISO 9001-2015 Certified Company by BSA established and providing welding solutions since 1990. Our work meets Automotive Industry Standards including 150+ various products and more than 10+ rigorous special processes. Our Head Office is located at Coimbatore providing Low, Medium and High Volume Manufacturing such as Laser Welding, Special process which includes Welding, Furnace Brazing, Sub Assembly & Fabrication. We also provide specialized furnace brazing solutions at Chennai. We do provide Flexible business models with customizable options to our clients.

Equipments Utilized

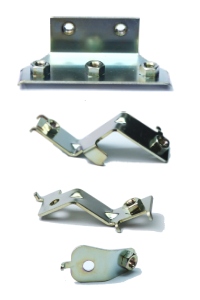

Our ability to work with a range of materials including mild steel, aluminium, stainless steel and brass, combined with the fact that we handle projects from beginning to end if needed, means that we can take on whatever requirements our clients come to us with.

Built with Confidence

The facilities that we offer our clients are a prime example of our commitment to flexibility, excellence and continuous improvement. Whether they come to us needing intricate fine work on components that will be highly visible or are extremely safety critical, coded welders or heavy welding on larger structures such as the chassis of a motor vehicle, clients can be sure that we’ll have just the right combination of high-tech equipment and experienced technicians needed to deliver their requirements in full.

Our purpose-built facility is equally able to handle Free Issue components and welding which forms part of full production, and we can handle everything from the smallest bracket to large-scale fabrications and assemblies.